In order to produce injection molds I work together with toolmakers from The Netherlands, Serbia and Portugal. Because every product is different and has its specific requirements, I select the right toolmaker for that product. You can assume that the latest techniques will always be used, for example I’ve already been using inserts in the molds that are created with DMLS (direct metal laser sintering) for a few years. This will give the mold the optimal temperature. I can also help with mold flow analyses and/or static analyses. I work closely together with a partner in Portugal to do this. I can also produce test molds. Depending on the product very fast delivery times are possible.

Molds

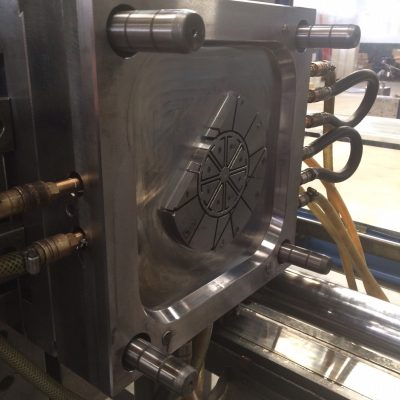

Pressure distribution disc

Pressure distribution disc

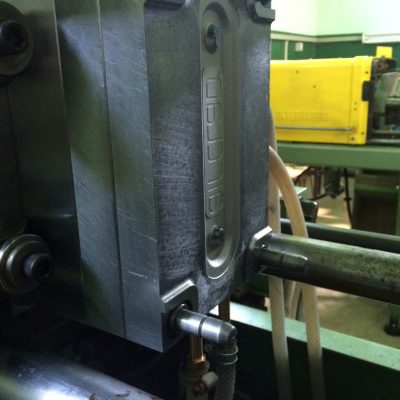

Mold foot fance

Mold foot fance made in Serbia

Cover plate second version

This single mold is produced in Serbia

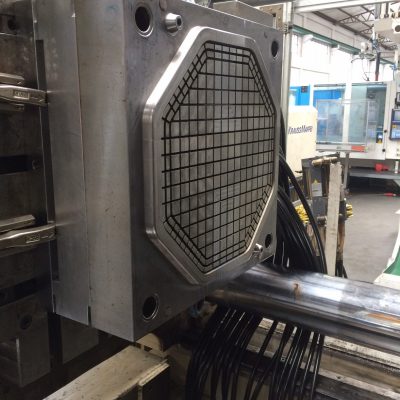

Mold panels

P

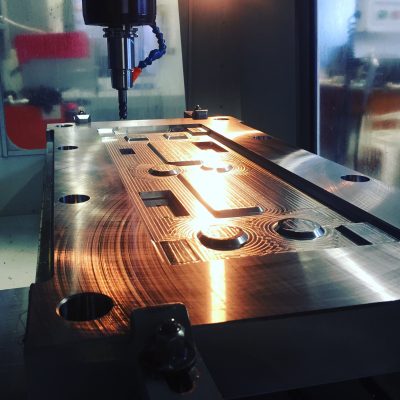

DMLS insert

DMLS insert from Portugal (Direct metal laster sintering) Ultimate cooling untill just beneath the surface of your insert, hardness can be up until 50 HRC

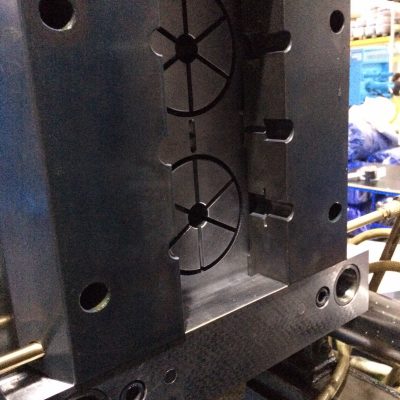

2 fold slide mold

2 fold slide mold build in Serbia

Ring mold

2-fold Portugese mold

4-fold cap mold

4-fold cap mold

Pressure distribution disc

Single portugese mold

Pressure distribution foot

Pressure distribution foot

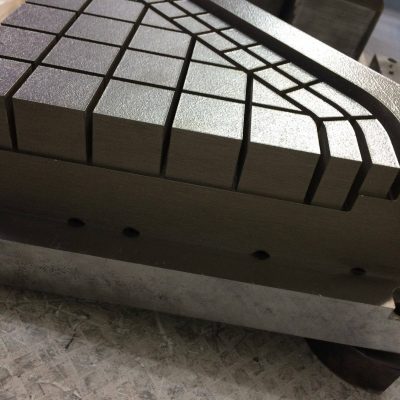

Mold insert plate

Mold insert plate is produced in Portugal. Inserts are made with DMLS for optimal cooling

Cover plate

This single mold is produced in Serbia

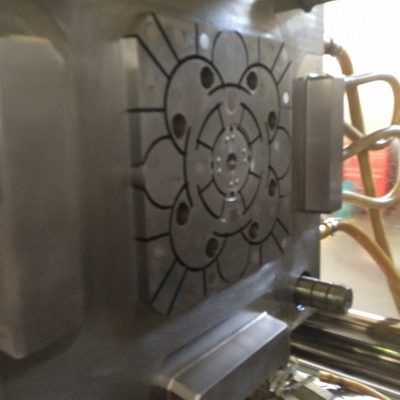

Insert DMLS

DMLS insert, cooling close to surface

Cover plate second version

Single mold from Serbia

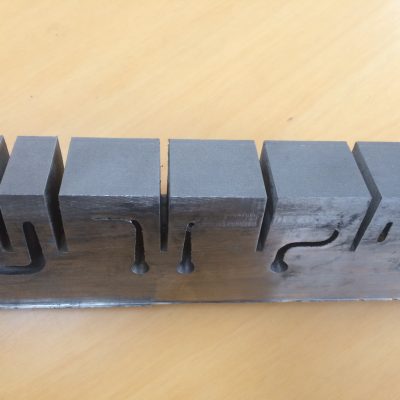

Test mold

Test mold bould in 4 weeks in Serbia

Coverplate

Single mold cover plate

2K Mold

Pressure distribution foot

[evp_embed_video url=”https://rupla.nl/wp-content/uploads/2016/10/IMG_6367.mov”]